San Diego’s two largest universities are developing ventilators for COVID-19 patients that could cost less than a flight to New York and back.

UC San Diego estimates that its model costs $500. San Diego State University estimates $550 for its model. High-end ventilators can cost up to $50,000.

With any luck, the ventilators will never be used in San Diego. The county’s hospitals have had enough ventilators to care for patients thus far.

But that could change if a surge in cases overwhelms the health care system. And there are plenty of other countries in need of affordable ventilators.

The inspiration for respiration

Most COVID-19 patients recover without needing specialized medical care. But in some cases, the disease damages people’s lungs so badly that they struggle to breathe on their own.

That’s where ventilators come in. These machines deliver controlled amounts of air to the lungs to keep the body supplied with oxygen.

Surges in Wuhan, China, as well as in New York and Italy raised fears that ventilator supply might not keep up with demand in regions hit hard by the pandemic.

Local medical equipment company ResMed, which usually makes sleep apnea machines, switched to make tens of thousands of ventilators. And researchers from San Diego to Boston to Barcelona began working on simpler, cheaper designs.

“When we originally started, we thought that there was going to be a huge demand for ventilation systems in San Diego,” said Kevin Wood, a mechanical engineer at SDSU. “We were really focused initially on meeting the needs of the local area.”

Wood’s expertise is in battery research, not medical devices. But he and his lab answered a call from the U.S. Department of Defense in March for low-cost, easy-to-assemble ventilator proposals.

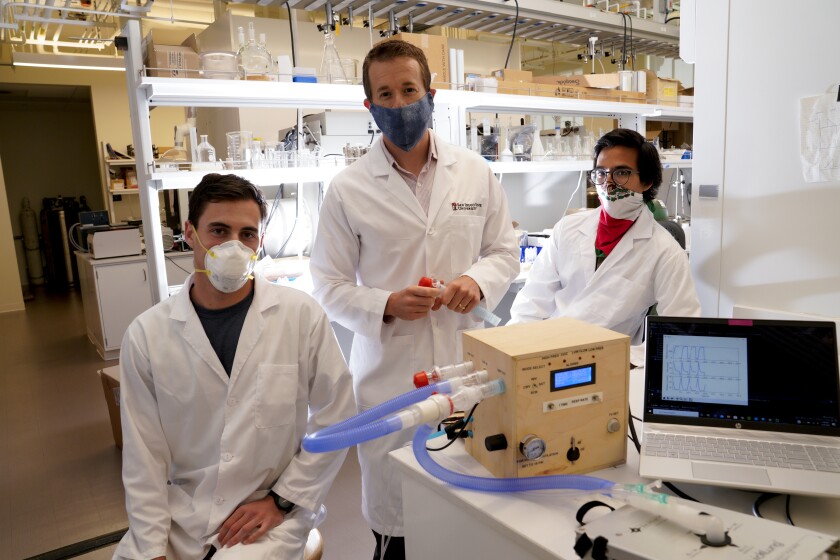

Kevin Wood (center), an assistant professor of mechanical engineering at San Diego State University, shows his design for an inexpensive ventilator that he and mechanical engineer Tyler Lestak (left) and mechanical engineering graduate student Ener Arvizu Muoz (right) designed and built.

(Nelvin C. Cepeda / The San Diego Union-Tribune)

Researchers at UCSD’s Jacobs School of Engineering also made a quick pivot after seeing concerning reports from Italy’s hospitals.

“It was almost, ‘Tools down. Whatever you’re doing, we’re now doing ventilators,’” said Dr. Lonnie Petersen, a physician-scientist and faculty member at the Jacobs School.

To keep costs low, both groups of researchers started with the simplest design possible — pushing air through a bag connected to a tube that would feed into a person’s airway.

First responders use a similar setup on patients struggling to breathe en route to a hospital. But instead of compressing the bag by hand, researchers mechanically compressed the bags.

That was a good start, but it was too simple a solution, said Petersen, who has worked in intensive care units as a physician. Some COVID-19 patients’ lungs are so weak that they need the ventilator to do all the work for them, while others simply need a little extra help breathing.

Petersen and colleagues tweaked their bare-bones design by adding a couple of sensors to measure the pressure of the air they deliver and how that affects the patient. Wood and his team made similar adjustments.

“The ventilation provided by the bag [is] really tailored to the patient,” Petersen said. “If the patient changes, progresses in disease or recovers a little bit, the system can adapt.”

Both teams also designed their ventilators to control the amount of oxygen they deliver. Wood’s ventilator, for example, can deliver increasingly higher doses of oxygen, up to 100 percent. Blood oxygen levels in COVID-19 patients can dip dangerously low, even in patients who don’t feel short of breath; long periods of oxygen deprivation can damage the heart and brain.

But while these simpler, cheaper ventilators are helpful in a crisis, they’re not a permanent substitute for standard models, said Dr. Jess Mandel, chief of pulmonary critical care and sleep medicine at UC San Diego. Standard ventilators can cost tens of thousands of dollars because they use a complex array of sensors that enable health care workers to fine-tune and monitor a patient’s air supply.

“There is a cheap, quick and dirty aspect to it, and that’s both its strength but also its weakness,” said Mandel, who is aware of both projects but was not a member of either team. “It’s certainly more limited than the types of ventilators that we use.”

Global applications

Neither group’s device has been cleared for use yet. They’ll need emergency use authorization from the U.S. Food and Drug Administration to deploy their ventilators in the United States.

The UCSD team has applied for authorization and is waiting to hear from the FDA; Wood and the SDSU group plan to apply soon. UCSD researchers have already shared their design online for anyone to adopt and adapt.

Wood said he has been in touch with physicians in Tijuana and officials at COFEPRIS (Mexico’s equivalent of the FDA) about getting the device approved for use in Mexico. That will likely involve additional animal experiments, he said. Wood said he also has secured D&K Engineering, a local contract manufacturer, as a partner to produce the ventilators once he hears from regulatory officials.

Despite all the effort, both teams said they’d rather never see their ventilators used in San Diego.

“We’d love [for] these to never come into use,” Petersen said. “So really, social-distance, stay at home as much as possible, wash your hands and wear a mask.” ◆

"easy" - Google News

June 29, 2020 at 10:02PM

https://ift.tt/2NFOiK8

UCSD and San Diego State developing low-cost, easy-to-make ventilators for COVID-19 patients - La Jolla Light

"easy" - Google News

https://ift.tt/38z63U6

Shoes Man Tutorial

Pos News Update

Meme Update

Korean Entertainment News

Japan News Update

Bagikan Berita Ini

0 Response to "UCSD and San Diego State developing low-cost, easy-to-make ventilators for COVID-19 patients - La Jolla Light"

Post a Comment